¶ How to make ElephantEdge counterweights

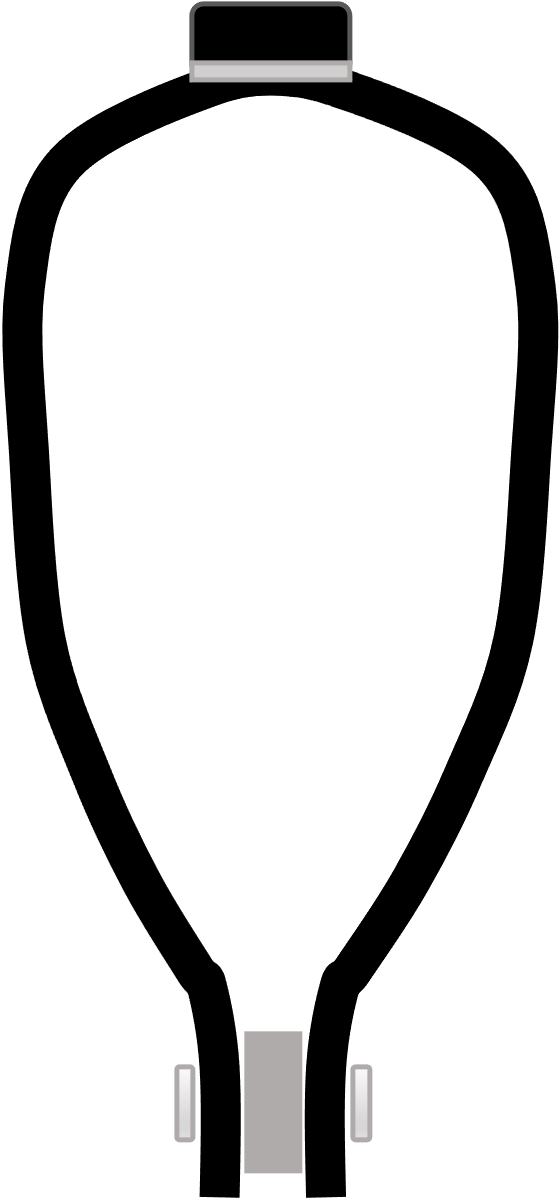

Our ElephantEdge devices do not include counterweights for the simple reasons that shipping lead units around the globe is (due to the weight) extremely expensive and secondly it is relatively easy to produce yourself. Therefore, this step-by-step explanation on how to make your own elephant collar counterweights.

Lead is the perfect material because it is very heavy. Using lead from old car batteries, some welding skills and patience we produced 5 KG lead counterweights.

In addition to the below step-by-step description, a short YouTube video on the process:

Credits to the Gonarezhou National Park workshop team.

¶ Step 1. Find old lead-acid batteries

Find old (sealed) lead-acid batteries that have preferably been outside in the scrap yard for a while, the weather will have “washed” away a lot of the acid. Most car batteries contain lead. Break the batteries open and collect the pieces of lead.

¶ Step 2. Neutralise battery acid

Leaking battery acid is harmful — it damages surrounding materials while also posing physical risks.

It’s not referred to as an acid for nothing – it burns and we’re not simply talking about your skin. For the average corroded battery, you should at least equip yourself with rubber gloves and long sleeves. Larger batteries pose greater dangers: Use goggles to cover your eyes, tie your hair back if necessary, and cover your mouth with a basic allergy mask.

Using hot water and baking soda, you can neutralise the battery acid left on the lead. Fill a bucket/tub with hot/warm water and mix with the baking soda (one tablespoon of baking soda per cup of water). We used about a 1 kg of baking soda.

The baking soda will react by bubbling up quite ferociously for a couple seconds. The reaction between the baking soda and water mixture and the acidic corrosion on the battery will neutralise the acid, making it safe to handle.

¶ Step 3. Weld a steel mould

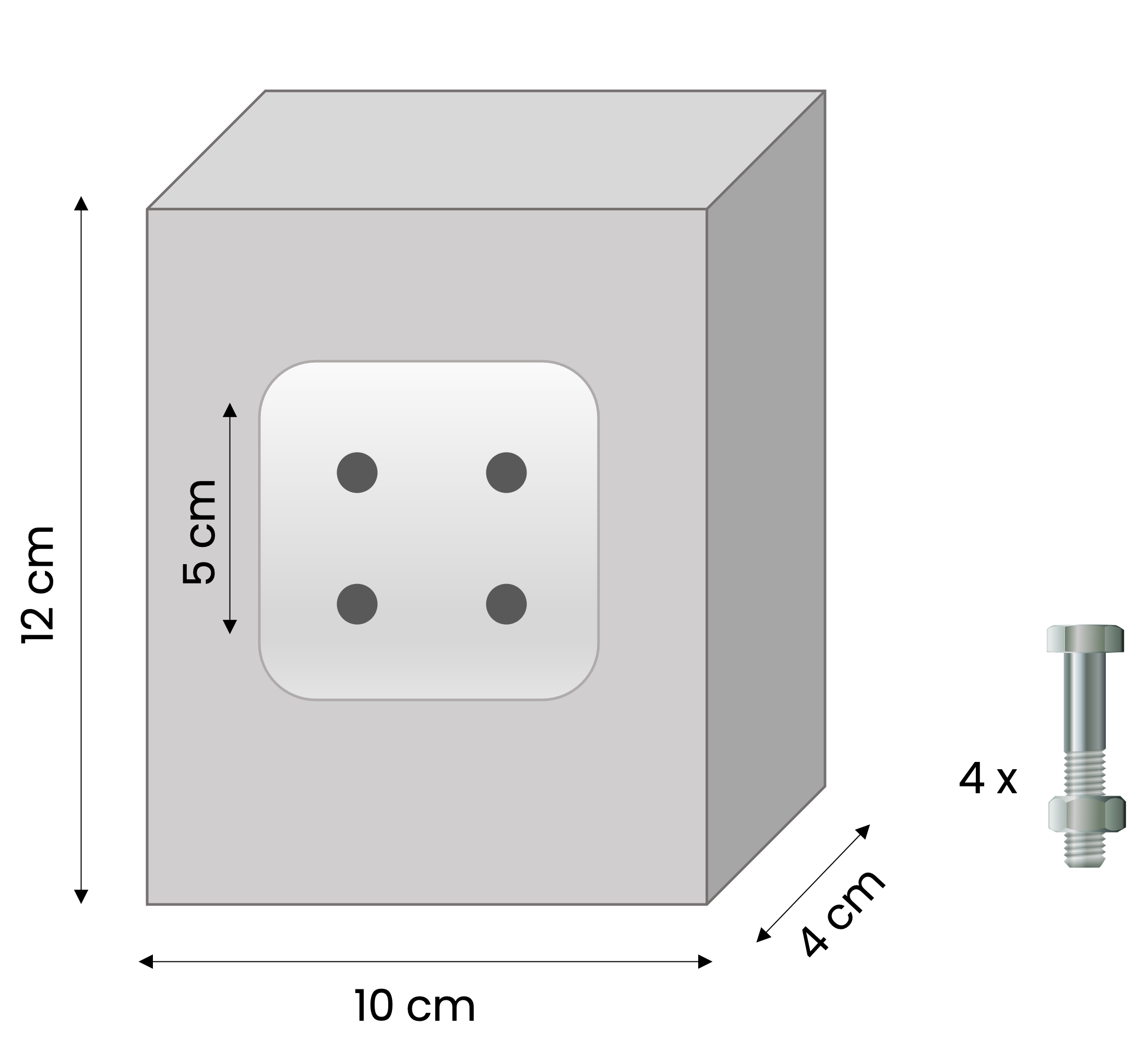

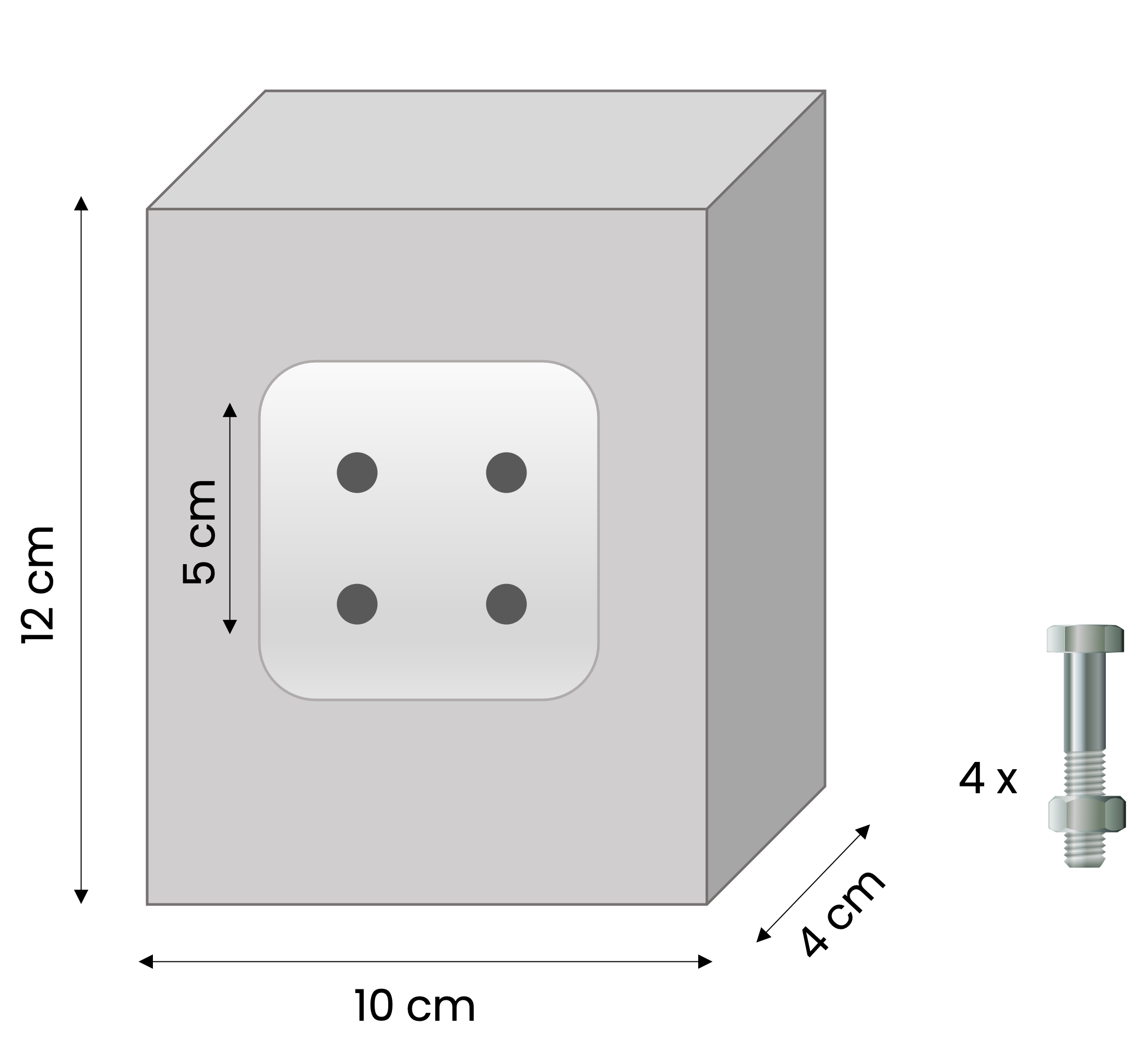

Using steel we welded a steel mould. Lead weights roughly ~11 grams per cubic centimeter. Our mould was 10 centimeters wide, 12 centimeters long and 4 cm high, which would roughly be equivalent to a 5.2 kg lead weight. Enough weight to counterweigh the Smart Parks ElephantEdge devices (1600 grams). Make sure the mould does not have any leaks (we tested this by pouring water in).

¶ Step 4. Melt the lead

Lead has a relatively low melting point (328 °C), so it is ideal for casting into shapes. That said, melting lead must be done with extreme caution and diligence, because it presents major burn, fire, and poisoning hazards.

We melt the lead using a blow torch and a steel pan (we made the pan out of an old John Deere oil filter). Apply the heat as directly to the lead as possible, larger amounts of lead will take time to melt. Remove the excess particles that will float to the surface.

¶ Step 4. Pour the lead in the mould

Once the lead is completely melted, pour it into the steel mould. Make sure the mould is placed on a flat surface, we used the sand surface to level. Turn off the heat source and work quickly to put the lead into the mould before it cools and solidifies.

¶ Step 5. Cool the lead in cold water

Allow the lead to cool in the mold for around 10 minutes. The lead will likely solidify within 2-3 minutes. For your safety and for better results, though, wait at least 10 minutes before trying to remove the lead from the mould. We cooled down the mould in cold water.

¶ Step 6. Smooth the edges using a hammer.

Sharp edges might hurt the elephants skin on the chest when the weight dangles down. Lead is very soft material, using a hammer (or other tool) you can smooth the sharp corner edges of the counterweight.

¶ Step 7. Drill holes in the weight to be able to attach the plates/belting

The counterweight is attached to the belt using two steel square (5 x 5 cm) plates with 4 holes (spaced at 3 cm from each-other at center) for the 4 6MM bolts to hold the weight in place. The belt should be placed between the steel plate and the lead counterweight, the 4 bolts are put through (steel plate - belt - counterweight - belt - steel plate) all layers.